Strategic Overview

In today’s competitive logistics landscape, selecting the right Warehouse Management System (WMS) and Transportation Management System (TMS) represents one of the most critical technology investments your organization will make. These systems form the operational backbone of efficient supply chain management, directly impacting customer satisfaction, operational costs, and competitive positioning. This comprehensive guide provides a strategic framework for making informed decisions that align technology capabilities with business objectives.

Strategic WMS and TMS Selection: Building the Foundation for Logistics Excellence

(WMS与TMS系统战略选择:构建物流卓越运营基础)

The complexity of modern supply chains demands sophisticated technology solutions that can adapt to evolving customer expectations, regulatory requirements, and market dynamics. Organizations investing in logistics technology today must balance immediate operational needs with long-term strategic flexibility, ensuring their chosen systems can scale and evolve with their business.

1 • Understanding Core System Functions and Strategic Value

Before evaluating specific solutions, successful technology selection begins with a clear understanding of how WMS and TMS systems create operational value and competitive advantage.

Warehouse Management Systems: The Central Command Center

A modern WMS serves as the operational nerve center of your warehouse or distribution center, orchestrating every movement and transaction within your facility walls.

Core WMS Capabilities:

Inventory Optimization and Control: Modern warehouse operations require real-time visibility into inventory levels, locations, and movement. A comprehensive WMS provides granular tracking of every item, from receipt through shipment, including lot numbers, expiration dates, and serial number management. This level of control enables organizations to maintain optimal stock levels while minimizing carrying costs and preventing stockouts.

Dynamic Labor Management: Effective warehouse operations depend on optimal labor utilization. Advanced WMS solutions provide intelligent task assignment, performance tracking, and productivity analytics. These systems can dynamically balance workloads across shifts, identify training opportunities, and optimize labor costs while maintaining service levels.

Automated Process Orchestration: Modern warehouses integrate multiple automation technologies, from conveyor systems to robotic picking solutions. A sophisticated WMS serves as the orchestration layer, coordinating automated and manual processes to maximize efficiency and accuracy throughout the operation.

Quality Assurance and Compliance: Regulatory requirements and quality standards continue to evolve across industries. Leading WMS solutions provide built-in quality control processes, compliance documentation, and audit trail capabilities that ensure operations meet or exceed required standards.

Transportation Management Systems: Optimizing the Supply Chain Network

TMS solutions extend operational control beyond the warehouse, optimizing transportation networks and carrier relationships to deliver cost-effective, reliable freight movement.

Strategic Transportation Planning: Effective transportation management requires sophisticated planning capabilities that consider multiple variables including carrier capacity, service levels, costs, and delivery requirements. Advanced TMS solutions provide optimization engines that can evaluate thousands of routing and carrier combinations to identify the most cost-effective solutions.

Carrier Relationship Management: Modern supply chains rely on complex carrier networks spanning multiple modes and service providers. A comprehensive TMS centralizes carrier management, enabling organizations to leverage their full transportation network while maintaining visibility and control over service performance.

Real-Time Shipment Visibility: Customer expectations for shipment visibility continue to increase across all industries. Leading TMS solutions provide real-time tracking and communication capabilities that keep customers informed while enabling proactive exception management.

Financial Optimization and Analytics: Transportation often represents a significant portion of total logistics costs. Advanced TMS solutions provide detailed cost analysis, audit capabilities, and optimization recommendations that can identify substantial savings opportunities while improving service levels.

2 • Strategic Evaluation Framework: Aligning Technology with Business Objectives

Successful system selection requires a structured approach that evaluates technology capabilities against specific business requirements and strategic objectives.

Comprehensive Needs Assessment

Business Process Analysis: Understanding current state operations provides the foundation for effective technology selection. Organizations should conduct detailed analysis of existing workflows, identifying inefficiencies, bottlenecks, and improvement opportunities. This analysis should extend beyond current operations to consider planned growth, new service offerings, and evolving customer requirements.

Performance Gap Identification: Quantifying performance gaps helps establish clear success criteria for technology investments. Organizations should identify specific operational challenges such as order accuracy issues, inventory discrepancies, transportation cost overruns, or service level failures that technology solutions can address.

Strategic Alignment Assessment: Technology investments must align with broader business strategies including growth plans, market expansion, customer service objectives, and competitive positioning. Systems selected today should support not only current operations but also planned strategic initiatives over the next 3-5 years.

Technology Capability Evaluation

Functional Requirements Analysis: Different organizations require different levels of system sophistication based on their operational complexity, industry requirements, and growth trajectories. A comprehensive requirements analysis should evaluate both current needs and anticipated future requirements across all relevant functional areas.

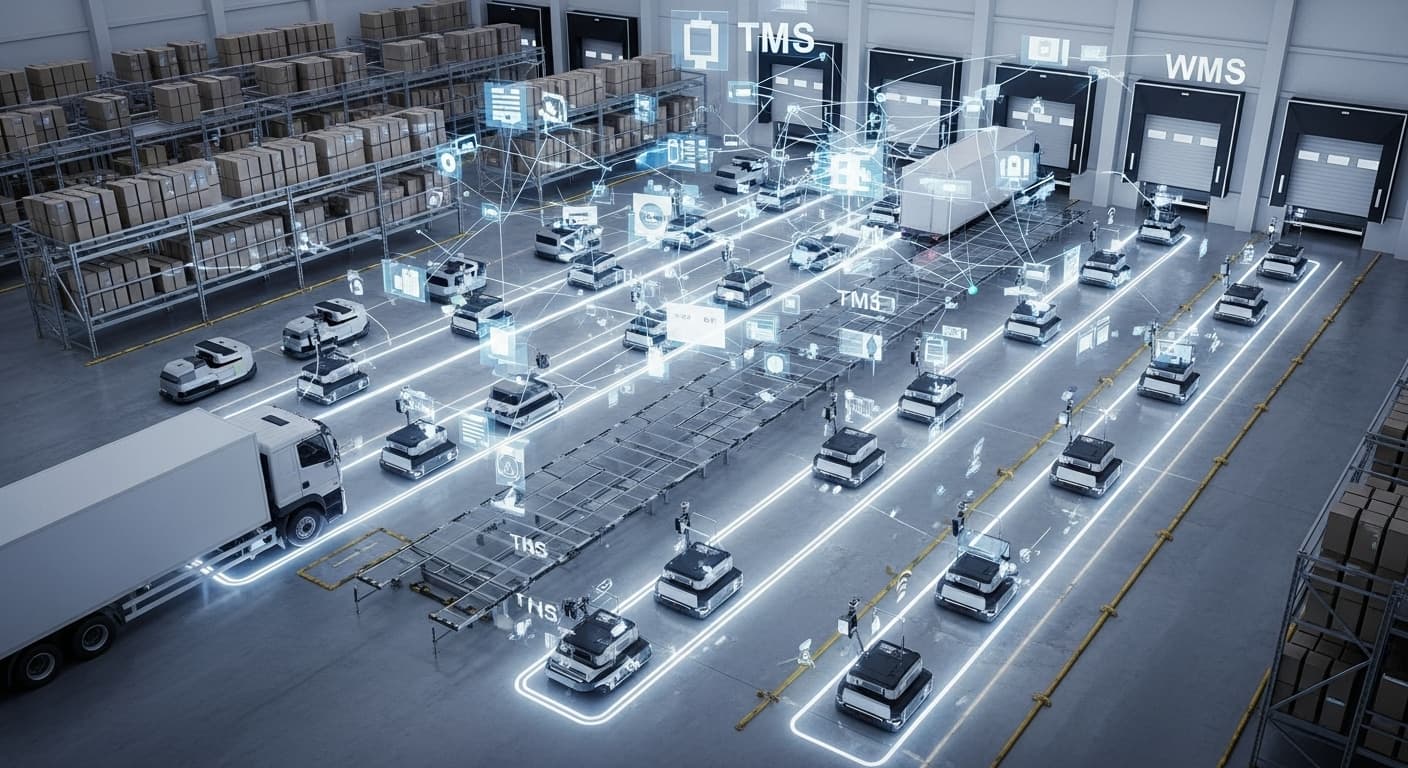

Integration and Interoperability: Modern logistics operations rely on multiple interconnected systems including ERP platforms, e-commerce solutions, customer portals, and carrier systems. Effective technology selection must consider integration capabilities and the total cost of system connectivity.

Scalability and Flexibility: Business requirements continue to evolve, driven by growth, market changes, and customer demands. Selected systems should provide the flexibility to adapt to changing requirements without requiring complete replacement or major customization efforts.

Vendor Evaluation and Selection

Market Position and Stability: Technology investments represent long-term partnerships that extend well beyond initial implementation. Organizations should evaluate vendor financial stability, market position, customer base, and long-term viability when making selection decisions.

Implementation and Support Capabilities: System implementation success depends heavily on vendor capabilities including project management, training resources, documentation quality, and ongoing support services. Organizations should carefully evaluate these capabilities as part of the selection process.

Innovation and Development Roadmap: Technology continues to evolve rapidly, with emerging capabilities in areas such as artificial intelligence, machine learning, and advanced analytics. Vendor development roadmaps and innovation strategies should align with organizational technology objectives and industry trends.

3 • Implementation Strategy and Change Management

Successful technology implementation requires comprehensive planning that addresses not only technical requirements but also organizational change management and user adoption.

Project Planning and Risk Management

Implementation Approach Selection: Organizations can choose from multiple implementation approaches including phased rollouts, parallel operations, or complete system replacements. Each approach offers different advantages and risk profiles that should be evaluated against organizational capabilities and operational requirements.

Resource Planning and Allocation: Effective implementation requires significant organizational resources including project management, technical expertise, user training, and change management. Organizations should develop comprehensive resource plans that ensure adequate support throughout the implementation process.

Risk Assessment and Mitigation: Technology implementations involve multiple risk categories including technical risks, operational disruption, user adoption challenges, and budget overruns. Developing comprehensive risk management strategies helps ensure successful implementation while minimizing business disruption.

Change Management and User Adoption

Organizational Communication: Successful technology implementations require clear, consistent communication throughout the organization. Stakeholders need to understand the business rationale for system changes, expected benefits, implementation timeline, and their role in ensuring success.

Training and Development: User competency directly impacts system effectiveness and ROI realization. Organizations should develop comprehensive training programs that address different user roles, learning styles, and proficiency levels while providing ongoing support and reinforcement.

Performance Monitoring and Optimization: Implementation completion marks the beginning rather than the end of system optimization. Organizations should establish performance monitoring processes that track key metrics, identify improvement opportunities, and ensure systems deliver expected business benefits.

4 • Technology Integration and Digital Transformation

Modern logistics operations require seamless integration between WMS, TMS, and other business systems to maximize operational efficiency and decision-making capabilities.

System Integration Architecture

Data Flow and Information Management: Effective logistics operations depend on accurate, timely information flow between systems. Organizations should design integration architectures that ensure data consistency, eliminate duplicate entry, and provide real-time visibility across all operational areas.

API and Connectivity Standards: Modern systems should support standard API protocols and connectivity options that facilitate integration with existing and future systems. Organizations should evaluate vendor API capabilities, documentation quality, and support for common integration platforms.

Cloud and Mobility Considerations: Cloud-based solutions offer advantages in terms of scalability, accessibility, and maintenance requirements. Organizations should consider cloud deployment options while evaluating security requirements, data governance policies, and connectivity needs.

Advanced Analytics and Intelligence

Operational Analytics: Modern WMS and TMS solutions should provide comprehensive analytics capabilities that enable data-driven decision making. Organizations should evaluate reporting capabilities, dashboard functionality, and the ability to create custom analytics that support their specific operational requirements.

Predictive Capabilities: Advanced analytics can provide predictive insights that enable proactive management of inventory levels, capacity planning, demand forecasting, and maintenance scheduling. Organizations should consider vendors’ capabilities in artificial intelligence and machine learning as part of their selection criteria.

Performance Benchmarking: Leading solutions should provide benchmarking capabilities that enable organizations to compare their performance against industry standards and best practices. This capability supports continuous improvement initiatives and helps identify optimization opportunities.

5 • Financial Analysis and Return on Investment

Technology investments require careful financial analysis that considers both direct costs and indirect benefits across multiple time horizons.

Total Cost of Ownership Analysis

Implementation Costs: Initial implementation costs include software licensing, hardware requirements, professional services, training, and internal resource allocation. Organizations should develop comprehensive budgets that account for all implementation-related expenses including potential business disruption costs.

Ongoing Operational Costs: Long-term operational costs include software maintenance, support services, infrastructure costs, and internal resource requirements. Organizations should evaluate vendor pricing models, support options, and upgrade policies when calculating total cost of ownership.

Hidden Cost Identification: Technology implementations often involve hidden costs including integration requirements, customization needs, additional hardware, network upgrades, and extended training requirements. Careful analysis should identify these potential costs early in the selection process.

Benefit Quantification and ROI Calculation

Direct Operational Benefits: WMS and TMS implementations typically deliver measurable benefits including labor productivity improvements, inventory optimization, transportation cost reduction, and accuracy improvements. Organizations should quantify these benefits based on current performance metrics and realistic improvement expectations.

Indirect Business Benefits: Technology investments often deliver indirect benefits including improved customer satisfaction, enhanced competitive positioning, better decision-making capabilities, and increased operational flexibility. While more difficult to quantify, these benefits can represent significant long-term value.

Risk Mitigation Value: Modern systems provide improved visibility, control, and compliance capabilities that help organizations mitigate operational risks. The value of risk reduction should be considered when evaluating total investment benefits.

6 • Industry-Specific Considerations and Requirements

Different industries have unique requirements that influence technology selection criteria and implementation strategies.

Regulatory and Compliance Requirements

Industry-Specific Regulations: Industries such as pharmaceuticals, food and beverage, and automotive have specific regulatory requirements that impact system selection. Organizations should ensure selected systems provide necessary compliance capabilities including lot traceability, temperature monitoring, and audit trail functionality.

Quality Management Integration: Many industries require integration between logistics systems and quality management processes. Organizations should evaluate vendor capabilities for supporting quality control workflows, documentation requirements, and compliance reporting.

Security and Data Protection: Increasing focus on cybersecurity and data protection affects system selection criteria. Organizations should evaluate vendor security capabilities, data protection measures, and compliance with relevant security standards and regulations.

Operational Complexity Considerations

Multi-Site Operations: Organizations operating multiple facilities require systems that can support centralized management while providing site-specific functionality. Evaluation criteria should include multi-site capabilities, centralized reporting, and standardization features.

International Operations: Global operations introduce additional complexity including multiple currencies, languages, regulatory requirements, and business practices. Organizations should evaluate vendor capabilities for supporting international operations and local requirements.

Seasonal and Peak Capacity Management: Many organizations experience significant seasonal variation in volumes and operational requirements. Selected systems should provide the flexibility and scalability to handle peak periods while maintaining efficiency during normal operations.

7 • Emerging Technologies and Future-Proofing

Technology selection must consider not only current capabilities but also emerging trends and future requirements that will impact logistics operations.

Artificial Intelligence and Machine Learning

Predictive Analytics Applications: AI and ML capabilities are increasingly being integrated into WMS and TMS solutions to provide predictive insights for demand planning, maintenance scheduling, and optimization. Organizations should evaluate vendor capabilities and roadmaps in these areas.

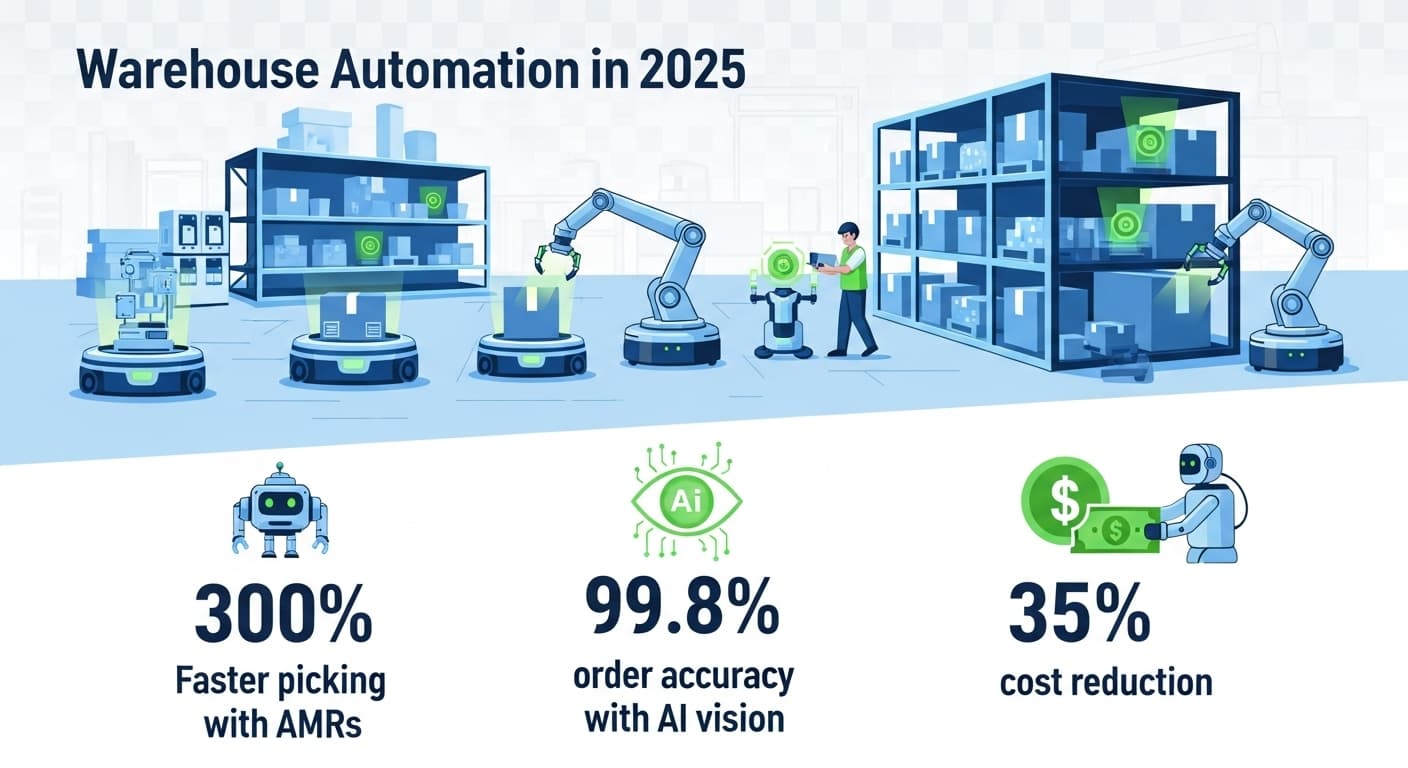

Automation and Robotics Integration: Warehouse automation continues to evolve with new technologies including autonomous mobile robots, automated storage and retrieval systems, and robotic picking solutions. Selected WMS solutions should provide the integration capabilities needed to support current and future automation investments.

Decision Support and Optimization: Advanced algorithms can optimize complex decisions including inventory positioning, labor allocation, routing optimization, and carrier selection. Organizations should consider these capabilities when evaluating system alternatives.

Internet of Things and Sensor Integration

Asset Tracking and Monitoring: IoT sensors enable real-time tracking and monitoring of assets, inventory, and environmental conditions. Modern systems should provide integration capabilities for IoT devices and sensor networks.

Predictive Maintenance: Sensor data can enable predictive maintenance capabilities for material handling equipment and automation systems. Organizations should consider how selected systems can leverage IoT data for maintenance optimization.

Environmental Monitoring: Industries with environmental requirements can benefit from integrated sensor monitoring for temperature, humidity, and other environmental factors. System selection should consider these requirements where applicable.

8 • Vendor Partnership and Long-Term Relationship Management

Technology selection establishes long-term partnerships that extend well beyond initial implementation. Successful vendor relationships require careful evaluation and ongoing management.

Vendor Assessment Criteria

Technical Capabilities and Innovation: Vendor technical capabilities should align with organizational requirements both currently and over the anticipated system lifespan. Organizations should evaluate development resources, innovation track record, and technology roadmaps.

Customer Success and Support: Ongoing support quality directly impacts system effectiveness and user satisfaction. Organizations should evaluate vendor support models, response times, escalation procedures, and customer satisfaction metrics.

Financial Stability and Market Position: Technology vendors should demonstrate financial stability and market position that ensures long-term viability. Organizations should evaluate vendor financial performance, market share, and competitive positioning.

Partnership Management Strategies

Performance Management: Successful vendor relationships require ongoing performance management including regular reviews, service level monitoring, and continuous improvement initiatives. Organizations should establish clear performance expectations and management processes.

Innovation Collaboration: Leading vendors often collaborate with customers on innovation initiatives and product development. Organizations should consider opportunities for influencing vendor roadmaps and participating in innovation programs.

Strategic Planning Integration: Vendor relationships should support organizational strategic planning through technology roadmap alignment, capacity planning, and growth strategy coordination. Regular strategic reviews help ensure continued alignment between vendor capabilities and business needs.

9 • Implementation Timeline and Project Management

Successful technology implementation requires comprehensive project management that coordinates technical, operational, and organizational requirements.

Project Phases and Milestones

Planning and Design Phase: Initial project phases focus on detailed requirements analysis, system design, integration planning, and resource allocation. This phase typically requires 8-12 weeks and establishes the foundation for successful implementation.

Configuration and Development: System configuration involves translating business requirements into system settings, workflow configurations, and integration development. This phase duration varies based on system complexity and customization requirements.

Testing and Validation: Comprehensive testing ensures systems meet functional requirements and perform reliably under operational conditions. Testing phases should include unit testing, integration testing, performance testing, and user acceptance testing.

Deployment and Go-Live: System deployment requires careful coordination to minimize operational disruption while ensuring successful transition to new systems. Deployment strategies should consider business requirements, risk tolerance, and operational constraints.

Success Factors and Best Practices

Executive Sponsorship: Successful implementations require strong executive sponsorship that provides resources, removes obstacles, and maintains organizational focus throughout the project lifecycle.

Cross-Functional Team Collaboration: Technology implementations affect multiple organizational areas including operations, IT, finance, and customer service. Cross-functional project teams ensure all requirements are addressed and stakeholder needs are met.

Communication and Change Management: Regular communication and structured change management help ensure user adoption and minimize resistance to system changes. Organizations should develop comprehensive communication plans that address all stakeholder groups.

10 • Strategic Recommendations and Decision Framework

Based on comprehensive analysis of WMS and TMS selection factors, several strategic recommendations emerge for organizations evaluating technology investments.

Decision Framework Elements

Strategic Alignment Assessment: Technology selection should begin with clear understanding of business strategy, operational requirements, and success criteria. Organizations should ensure selected systems support both current needs and strategic objectives over the anticipated system lifespan.

Comprehensive Evaluation Process: Effective vendor evaluation requires systematic assessment of functional capabilities, integration requirements, vendor qualifications, and total cost of ownership. Organizations should develop structured evaluation processes that ensure objective, comprehensive vendor assessment.

Implementation Planning: Technology implementations require comprehensive planning that addresses technical, operational, and organizational requirements. Successful implementation planning should include resource allocation, risk management, change management, and performance monitoring.

Success Factors for Long-Term Value Creation

User Adoption and Engagement: System effectiveness depends heavily on user adoption and engagement. Organizations should prioritize user experience, training quality, and ongoing support to ensure maximum system utilization and benefit realization.

Continuous Improvement: Technology investments should enable continuous improvement through enhanced analytics, process optimization, and performance monitoring. Organizations should establish improvement processes that leverage system capabilities for ongoing operational enhancement.

Vendor Partnership Management: Long-term success requires effective vendor partnership management including performance monitoring, relationship management, and strategic planning coordination. Organizations should invest in vendor relationship management to ensure continued value delivery.

Future-Proofing Strategies

Technology Evolution Preparation: Organizations should select systems and vendors with strong innovation capabilities and clear technology roadmaps. System architectures should support emerging technologies and evolving business requirements.

Scalability and Flexibility: Selected systems should provide the scalability and flexibility needed to support business growth and changing requirements. Organizations should avoid systems that require major reinvestment to accommodate growth or change.

Integration and Interoperability: Modern logistics operations require seamless integration between multiple systems and technologies. Selected solutions should support standard integration protocols and provide flexible connectivity options.

Conclusion: Building the Technology Foundation for Logistics Excellence

The selection of warehouse management and transportation management systems represents one of the most strategic technology decisions facing logistics organizations today. These systems form the operational foundation that enables efficient, accurate, and cost-effective supply chain operations while providing the flexibility needed to adapt to evolving market requirements.

Key Strategic Insights

Technology as Competitive Advantage: Organizations that approach WMS and TMS selection strategically, with focus on long-term value creation rather than short-term cost minimization, position themselves for sustainable competitive advantage through operational excellence and customer service leadership.

Integration and Ecosystem Thinking: Modern logistics success requires seamless integration between WMS, TMS, and other business systems. Organizations should prioritize integration capabilities and ecosystem compatibility when making selection decisions.

Future-Ready Architecture: Technology investments made today must support tomorrow’s requirements including emerging technologies, evolving customer expectations, and changing regulatory requirements. Forward-thinking selection criteria ensure long-term investment value.

Implementation Success Framework

Comprehensive Planning: Successful implementation requires comprehensive planning that addresses technical, operational, and organizational requirements. Organizations should invest adequate time and resources in planning to ensure successful deployment and adoption.

Change Management Excellence: Technology effectiveness depends on user adoption and organizational change management. Organizations should prioritize change management and user engagement throughout the implementation process.

Continuous Optimization: System implementation marks the beginning of continuous improvement and optimization. Organizations should establish processes for ongoing system enhancement and benefit realization.

Long-Term Value Creation

Operational Excellence: Well-selected and implemented WMS and TMS solutions enable operational excellence through improved accuracy, efficiency, and customer service. These capabilities translate directly into competitive advantages and financial performance.

Strategic Flexibility: Modern systems provide the visibility and control needed to respond rapidly to market changes, customer requirements, and competitive pressures. This strategic flexibility becomes increasingly valuable in dynamic market environments.

Innovation Platform: Leading logistics technology solutions serve as platforms for innovation, enabling organizations to leverage emerging technologies and implement new service offerings. This innovation capability supports long-term growth and competitive positioning.

The logistics technology landscape continues to evolve rapidly, driven by customer expectations, competitive pressures, and technological advancement. Organizations that approach WMS and TMS selection with strategic perspective, comprehensive evaluation processes, and long-term vision will build the technology foundation needed for sustained success in the modern logistics environment.

Success in technology selection and implementation requires balancing multiple considerations including functional requirements, cost constraints, implementation complexity, and future flexibility. Organizations that maintain focus on long-term value creation while ensuring thorough evaluation and planning will realize maximum return on their technology investments while building capabilities that support continued growth and competitive advantage.

This strategic guide provides comprehensive insights for WMS and TMS selection based on industry best practices and emerging trends. Advanced Logistics Solutions specializes in helping organizations navigate complex technology selection and implementation processes. Our team of logistics technology experts provides objective analysis and strategic guidance tailored to specific operational requirements and business objectives.